Peripheral unrolling is a variant of stroke embossing in terms of application technology.

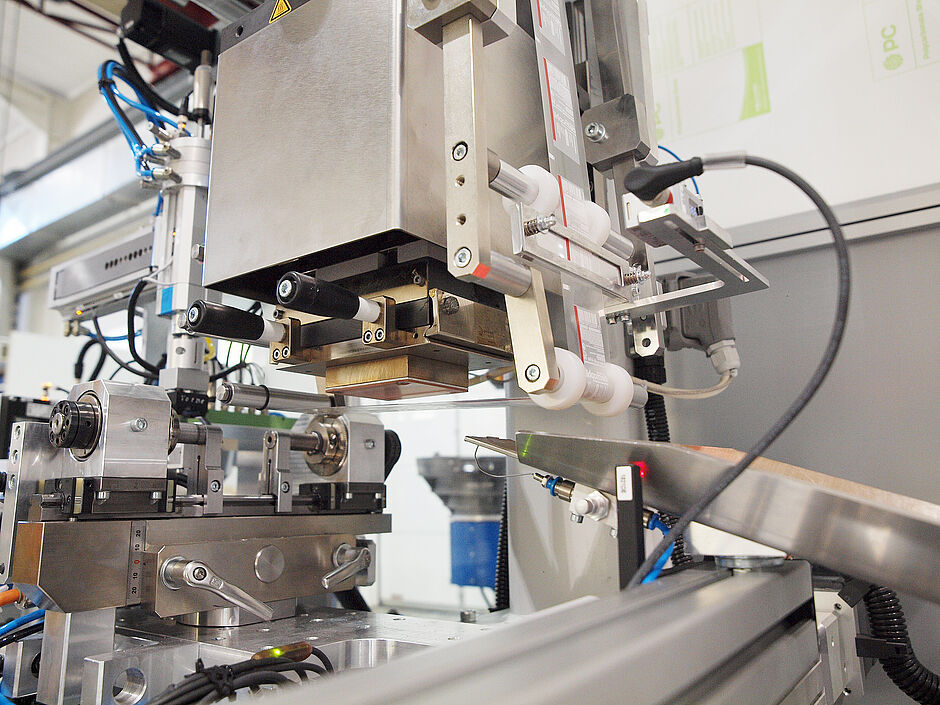

In contrast to conventional stroke embossing, the component is unrolled under a fixed punch even when the stroke of the embossing unit is extended. Unwinding is carried out via a servo-driven embossing mandrel or via a roller mill.

This means that both cylindrical and slightly conical components, such as those often found in the cosmetics industry, can be embossed.

Predestined components:

- Eye liner

- Lipstick

- Sleeves

- Cans

- Caps

- Number rolls, number ring

By means of automated part feeds and part storage in bunkers or vibratory conveyors (bulk material), but also a corresponding part discharge, up to 2000 parts per hour can be decorated, depending on the machine concept.