Maximizing effectiveness and production stability

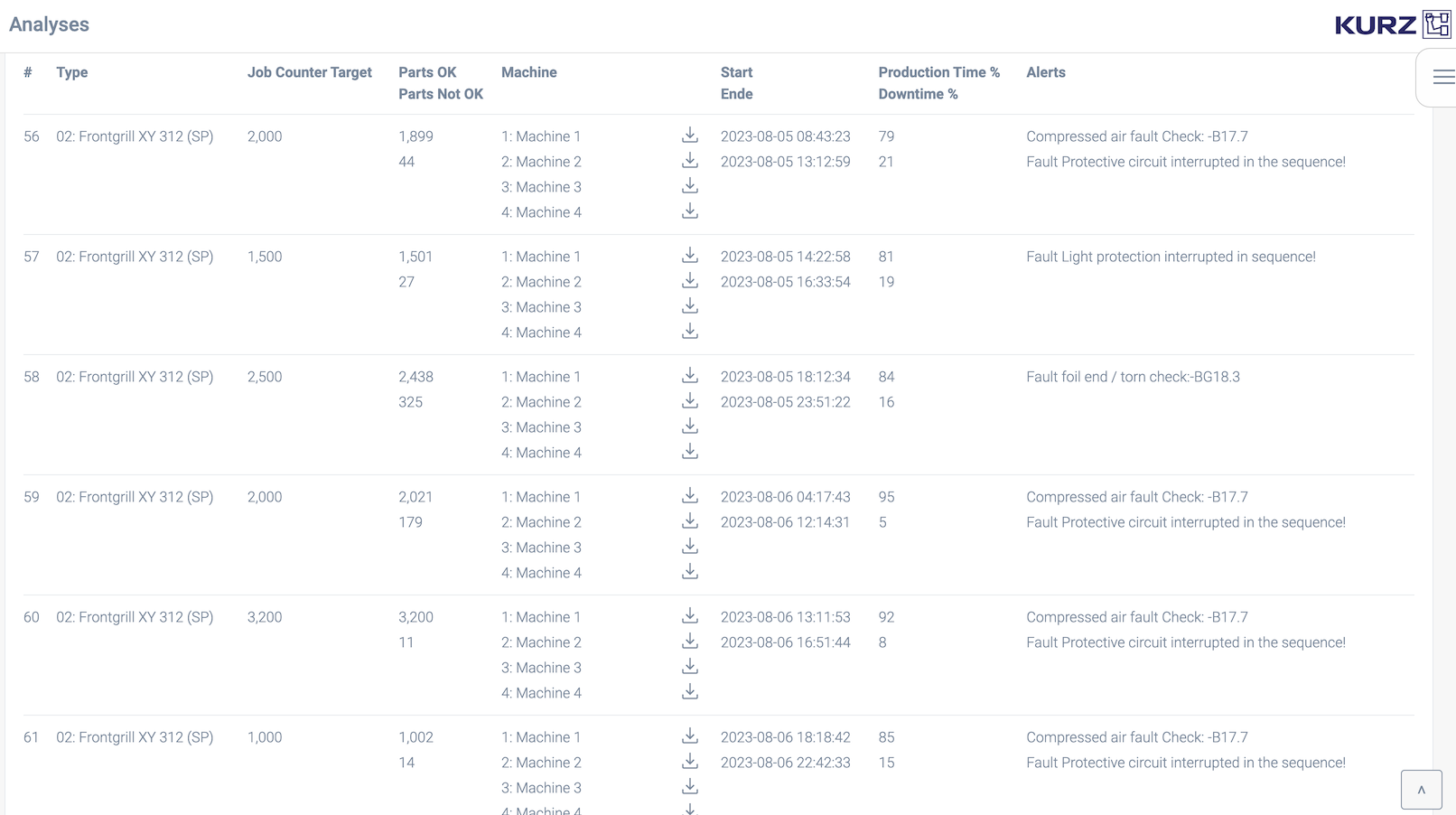

The hot-stamping process is permanently monitored. Each finished job is linked to the corresponding process data.

In this way, job data can be sent to the machines, the machines report the process data of the finished parts, the software collects this data and provides it to the connected systems. This means you can see which parts of a product were manufactured in which job and which process parameters, e.g., temperature, pressure, time, etc. were recorded during embossing.

Minimizing downtimes

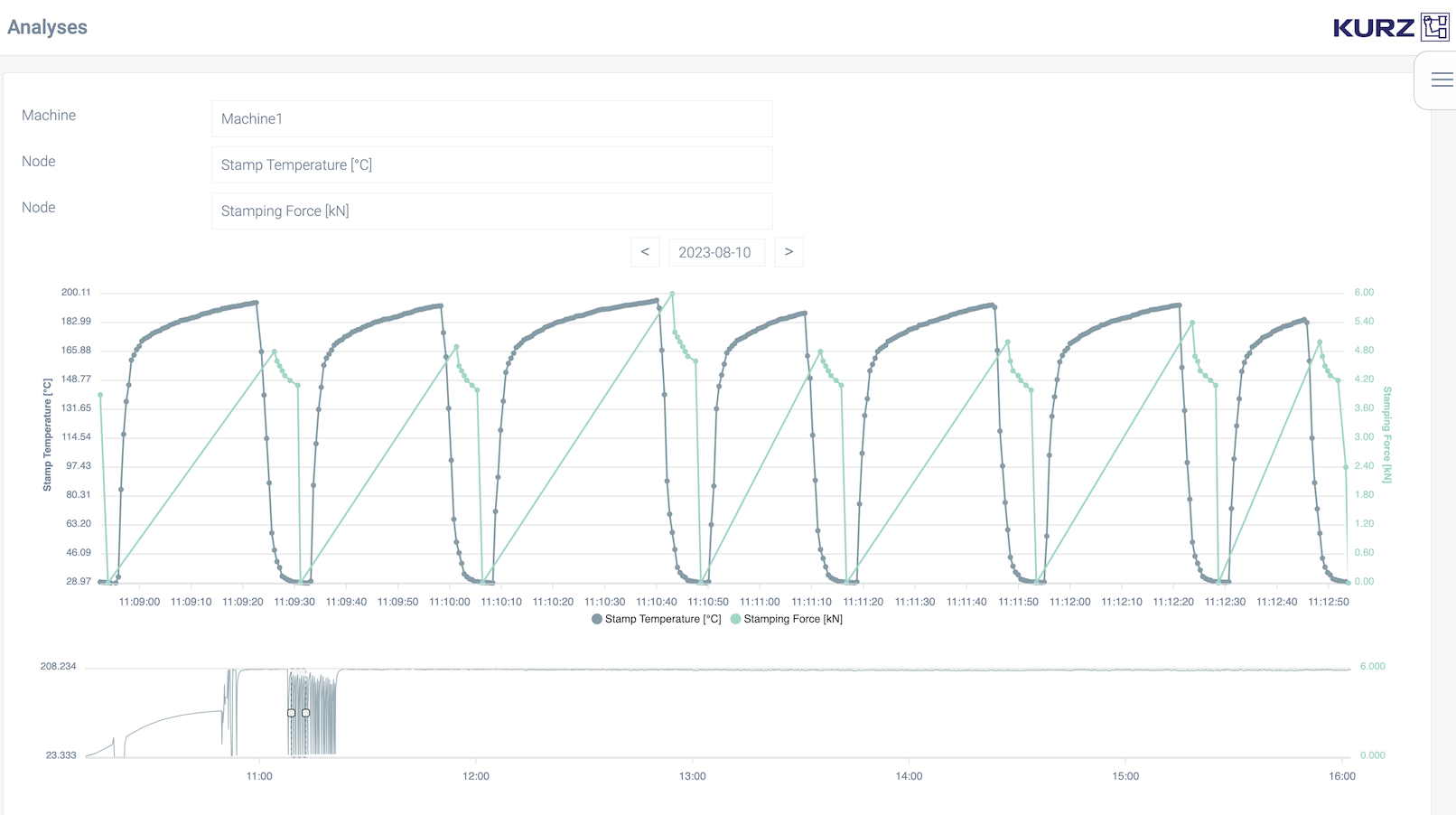

Hot stamping processes result in large data volumes that we have not used very much so far, so there is a lot of potential here. With KURZ Machine Insight Services, you have the opportunity to change this. With the software, you can increase production stability and thus process reliability and efficiency, as well as minimize downtime. The visual representation of selected parameters makes them clearer and easier to understand at a glance.

Shorter set-up times

A special feature of our software is that it reduces set-up times, as it provides a function for saving machine settings for each product type. This allows you to pre-plan production job and automatically transfer the corresponding machine adjustments or "recipes." This not only shortens set-up times, but minimizes repetitive manual input while supporting the reproducibility of production processes.

Early detection of problems and signs of wear

Not only does this software help you identify and fix problems faster, it goes even one step further. It uses artificial intelligence to analyze process data in real time and detect anomalies and signs of wear on the machine and tool at an early stage. This means that you’ll be able to predict and prevent incidents such as breakdowns or repairs.

Better planning through built-in operating data acquisition

The software records the process data of the machines and interprets them into useful operating data. As a result, you always have the most important key figures such as run times, downtime, and effectiveness readily available and can react quickly and plan better.

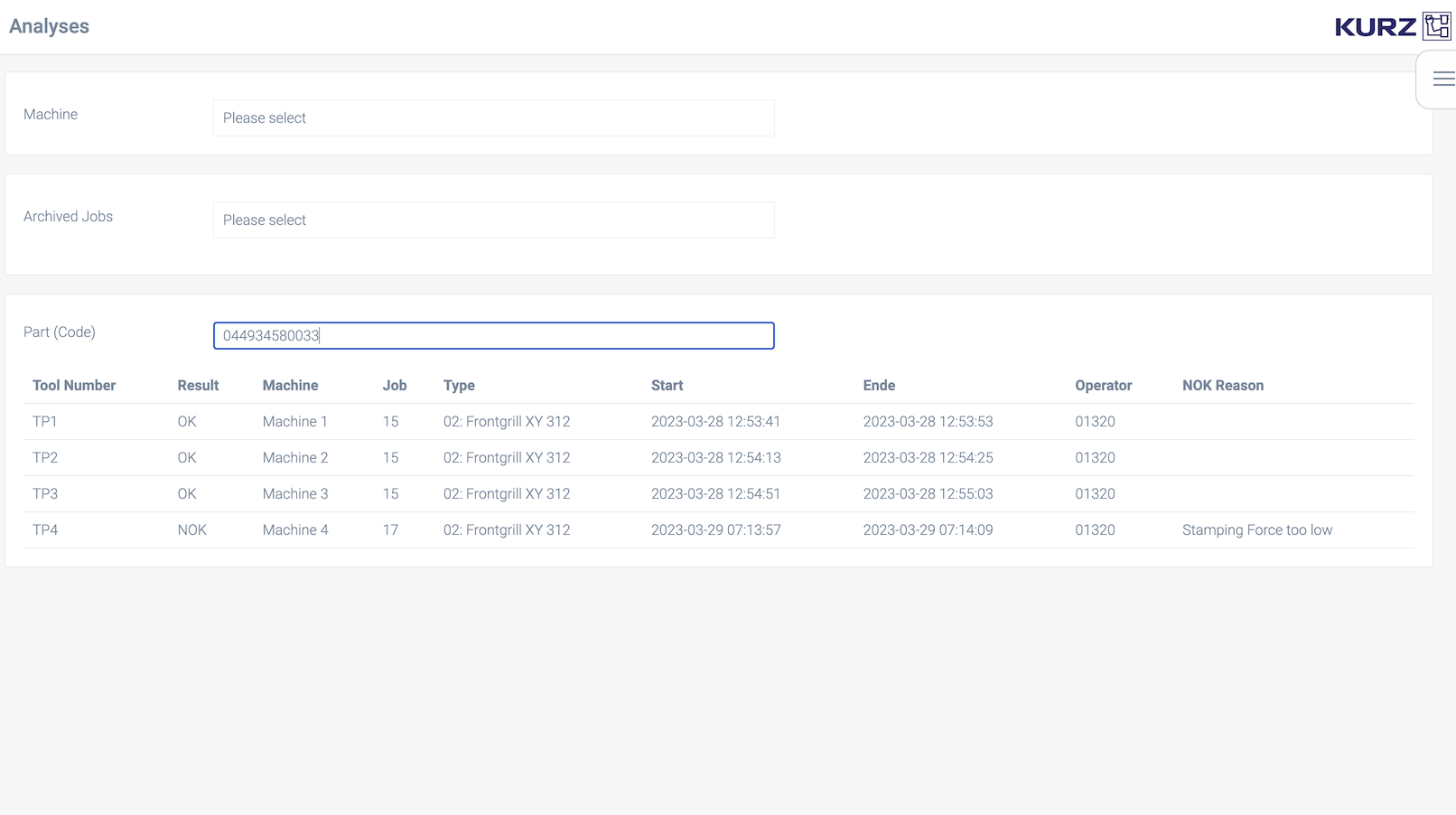

Parts traceability

This function also makes it possible to assign a unique part number to each part during embossing. For example, part numbers can be read in with barcode readers and assigned to an job. This makes tracking and checking the embossing process easier than ever before. When you enter the part number, you will find out in which job(s) and on which machine(s) the component was embossed. You can also view the component’s process parameters.

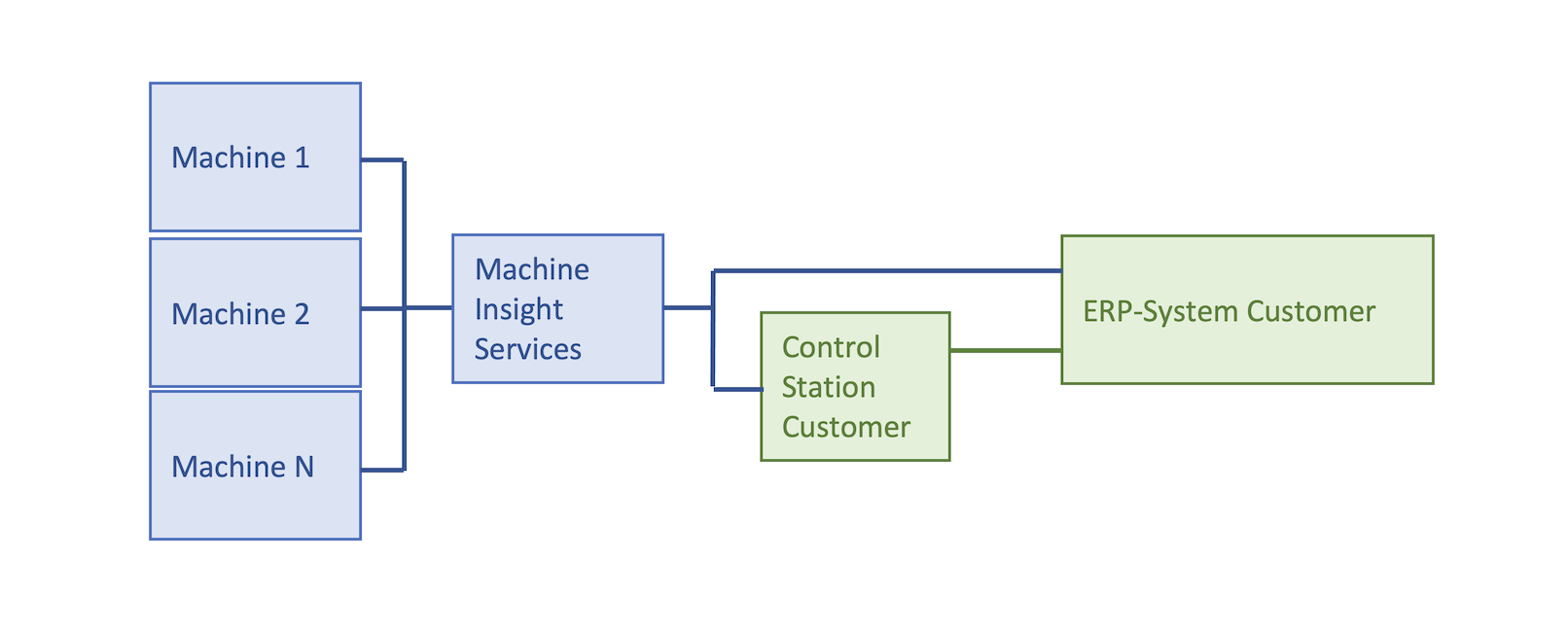

Your data and seamless integration with your systems

With this software, you can integrate your machines easily and seamlessly in your existing ERP/ measurement system or control station.

Whether you have only one machine or up to ten in one production cell, our software can easily be scaled to meet your needs. This also allows you to check whether a part has been embossed on each machine.

It is important to mention that the software is operated exclusively in your network, so that your data is always in your possession.

The software can be adapted to your needs. Choose from the following modules.

1. Parts traceability

A unique part number can be assigned to each part during embossing.

2. Orders and recipes

For each product to be manufactured (e.g., Type A radiator grille), the adjustments (recipes) of the machine can be stored.

3. Process and machine data

Recording of target and actual values of the machine parameters, operating data aggregation (operating times, downtimes, and effectiveness of machines; produced quantities)

4. Anomaly Detection/Predictive Maintenance

You can send us an extract of the accrued data in a secure manner. We will analyze this data and generate AI models for anomaly detection and predictive maintenance.

5. Management of stamps, images, and films

In product type recipes, the films, stamps, and images to be used can be stored.

6. Connecting existing systems

With these interfaces, you can connect your machines with your ERP and measurement systems and connect the control station. We will be happy to assist you.

7. Customer-specific software development

We can also fulfill your wishes and expand the software according to your needs.